CMS Overview

Product Description

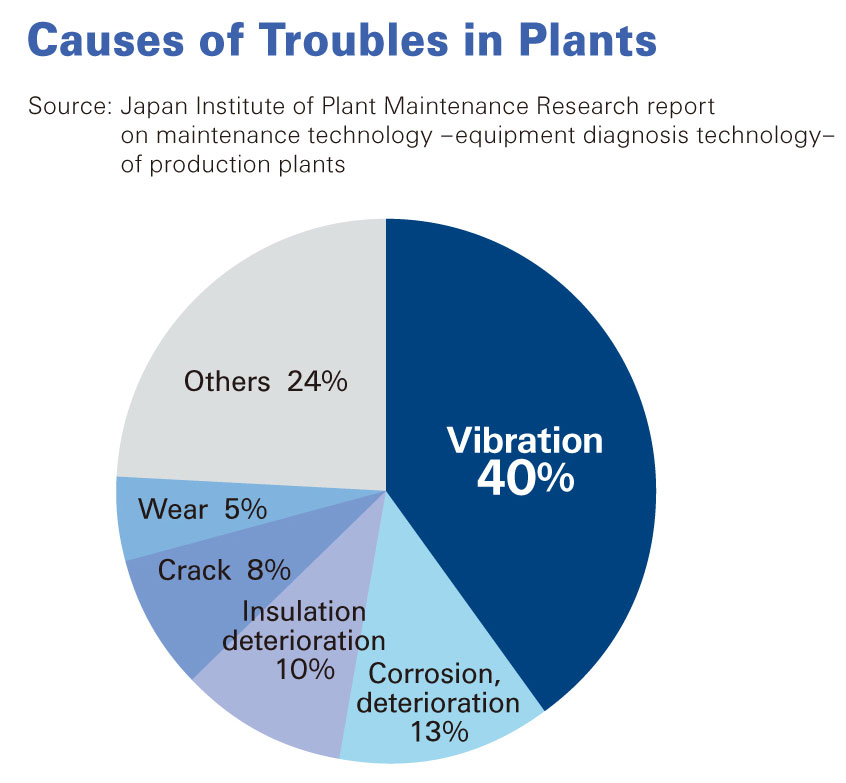

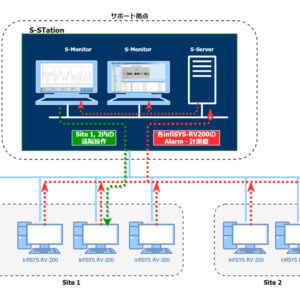

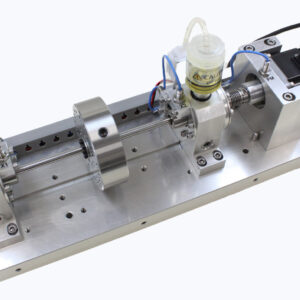

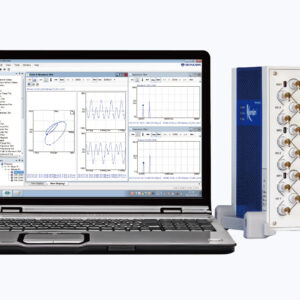

Rotating machinery that serves as the heart of plant equipments. The vibrations on these contain various important information. As a sensor manufacturer, SHINKAWA has always studied for and been there to protect rotating machinery. Using the proprietary program based on our expertise, we provide a system to analyze/diagnose the valuable data. Not only with the alarms in fault conditions, we support our customers with optimum scheduling of repair and maintenance by offering early detection of fault or abnormal condition, assumption of the cause or the area of the failure. SHINKAWA’s CMS helps our customers make right decisions on the equipment investment to manage cost and risks. The results will be improved operation efficiency with safe and stable operation.

SHINKAWA’s CMS detects failure symptoms at early stages with monitoring, analyzing and diagnosing vibration from rotating machinery. Prevent failures/accidents contributes to plant’s efficient, continuous safe operations.

View PDF

CMS helps to realize safe operation by accurately analyze/diagnose the vibration on rotating machinery.

- Reduce downtime with early detection

Failure indicators are based on changes in vibration levels and characteristics. Knowing what is going on, allows for proactive maintenance where downtime can be scheduled minimizing impact to production and profits. - Optimize production schedule

Production efficiency drives the profitability of a plant. Maintenance of the equipment optimizes time and costs resulting in managing profit risk. - Reliable and efficient maintenance

Proper sensor technology with necessary sophistication and precision provide the raw data for accurate analysis and diagnostics. This data allows for intelligent, timely and cost effective maintenance decisions by plant personnel. - Reduce total maintenance costs by moving from TBM to CBM

TBM is an excellent approach to servicing equipment; however, it is not the most cost efficient. Utilizing CBM is a proactive way to reduce costs, became more efficient, and have better knowledge of the equipment health.

TBM : Time Based Maintenance

CBM : Condition Based Maintenance - Allow empirical maintenance knowledge to be passed on

Maintenance professionals have “know-how” or empirical knowledge which is difficult to pass on. Having real life data with analysis helps create the “know-how” so any level of experience can benefit from the data. It is a scientific approach and reduces learning curves.

Be the first to review “CMS Overview”

Contact Details

Follow Our Services

We Are Everywhere

Reviews

There are no reviews yet.