SONAPHONE

Product Description

Ninety-nine percent of all bearings fail, and when they do, your production comes to a standstill.

How do you prevent a single component from crippling your entire facility? By predicting failures before they happen.

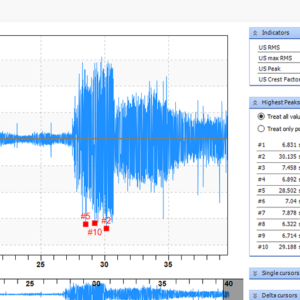

Your production depends on healthy, rotating assets. Bearing monitoring is one of many ultrasound applications that gauge the health of your factory. All bearings emit ultrasound signals that are masked by the sounds of your operation. Ultrasonic bearing monitoring enables you to hear, measure and trend these signals and decide if your asset is OK.

Most bearings do not live to their engineered lifecycle, and bad lubrication practices are the leading cause. Lubrication of bearings is one of the most misunderstood and abused tasks in the industry. Knowing when and how much to grease is the key to optimizing bearing lubrication. With ultrasonic bearing monitoring, you’re able to lubricate bearings based on their condition rather than on a fixed schedule. Predict relubrication intervals and add just the right amount of grease with SDT’s integrated ultrasound greasing solutions.

Be the first to review “SONAPHONE”

Contact Details

Follow Our Services

We Are Everywhere

Reviews

There are no reviews yet.